- Home

- About Us

- Products

- Wollin GmbH, GermanySpray Technology for Die Casting Foundries

- Krown SA, SpainIntegral Solutions for Aluminium Foundries

- Iruña Automation, SpainAutomating Industrial Processes in Foundries

- Chem-Trend L.P., USA Process Solutions For the Die Casting Industry

- TotalEnergiesLubrication Solution For Industrial Application

- Sunalco Alloys Pvt. Ltd.Secondary Aluminium Alloy

- Our Principals

- Clients

- Careers

- Contact Us

- info@jnjautoimpex.com

- +91 98224 96814 / 99708 22444

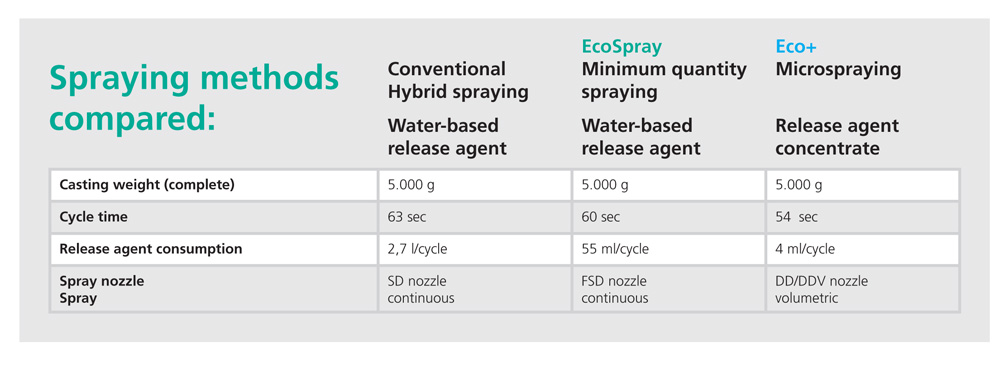

Eco+ and EcoSpray

Spray solutions with saving potential

Estimated savings with microspraying (Eco+) with Wollin EcoSpray

- Cycle time 10 - 20%

- Energy (mold tempering) 60 - 80%

- Compressed air (vol.) 70 - 80%

- Fresh water 99 - 100%

- Waste water 100%

- Mould life 50 - 300%

Reduction of scrap rate, easier rework, lower maintenance effort, significant increase in die service life up to 300%

In the die casting industry, the development of resource-saving technologies is a continuous endeavor. Wollin is taking the lead with the development of the patented Eco+ microspray technology.

Eco+ and EcoSpray essentially work with two developments:

- Application technology that optimizes the lowest spray quantities possible

- Improved release agents (oil/water-based) which operate at higher temperatures, up to 400°C

The use of oil- or water-based concentrates, combined with Eco+ micro-spray technology, offers:

- Economic advantages

- Ecological advantages

- Production advantages

- For Eco spray, the following equipment needed is:

- Spraying tool with FSD

- Release agent supply such as OSA 1-50-2 or OSA 2-15 - Expected outcomes using Eco spray:

- Resource-saving (when using an appropriate release agent)

- Better part quality

- Longer die service life

- Continuous spraying

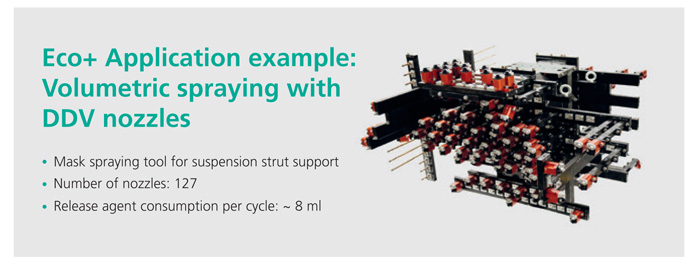

- For Eco+ spray, the following equipment needed is:

- Spraying tool with DD or DDV nozzles

- Release agent supply such as OSA 1-50-2 or OSA 2-15

- ECO-prepared mold spraying machine (ex works or retrofi tted)

- Pressure boosting station if air pressure network < 7 bar (only for DDV nozzles) - Expected outcomes using Eco spray:

- Resource-saving (when using an appropriate release agent)

- Better part quality

- Longer die service life

- Lower release agent consumption

- Higher process reliability

- Volumetric spraying